Good Designing

Design is the first look in automobile industry and we are the best designers in this field.

OnTime Delivery

On time delivery is the key indicator for customer relation. We provide our materials on this and keep the trust.

8+ Years Experience

Our company is engaged in manufacturing Die Spares Precision Tools Machined Components and many more.

- Manufacturing Process

- Sheet Metal Works

- Automobile Components

- Prototype Development

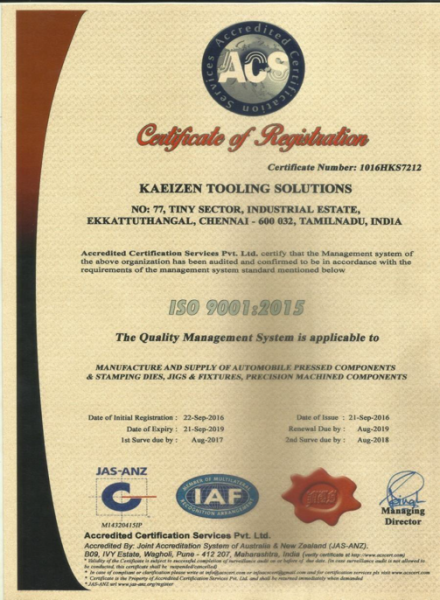

High Quality

The company had a reputation for building high-quality materials.

Low Cost

Kaeizen Tooling Solutions produce cost effective materials by improving the technology and time.